Raw Material Inspection

Conduct quality tests on purchased nicotine, and other materials to ensure they meet production standards.

We prioritize attention to detail, striving for impeccable product quality, and strictly adhere to GMP standards.

ISO and GMP certified manufacturing centers

Strict control of humidity and temperature

Independent ventilation and logistic systems

Our Production

Conduct quality tests on purchased nicotine, and other materials to ensure they meet production standards.

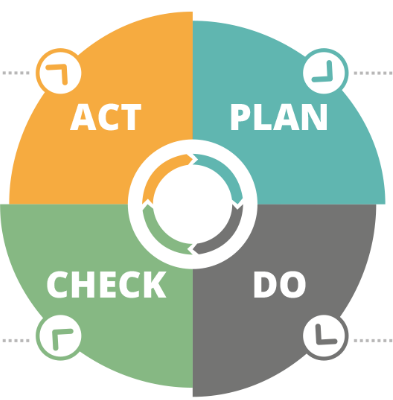

Good Manufacturing Practices (GMP), which help to ensure the quality of products.

Combine nicotine extract with shredded tobacco, flavorings, glycerin, and other ingredients according to the formula.

Shape the mixed materials into oral nicotine products, usually small pouches or pellets

Conduct quality inspections on finished products to ensure they meet the required standards.

Package the formed oral nicotine products, ensuring they are sealed and moisture-proof.

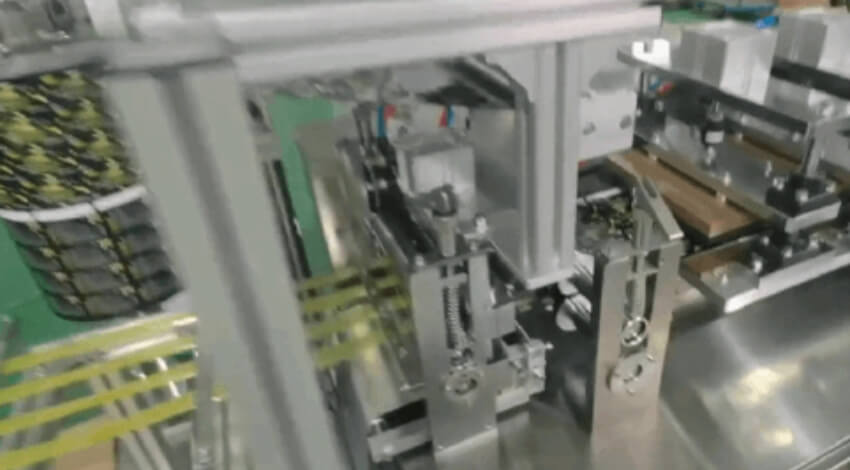

The oral dissolution film making machine can quickly produce oral film.

Good Manufacturing Practices (GMP), which help to ensure the quality of products.

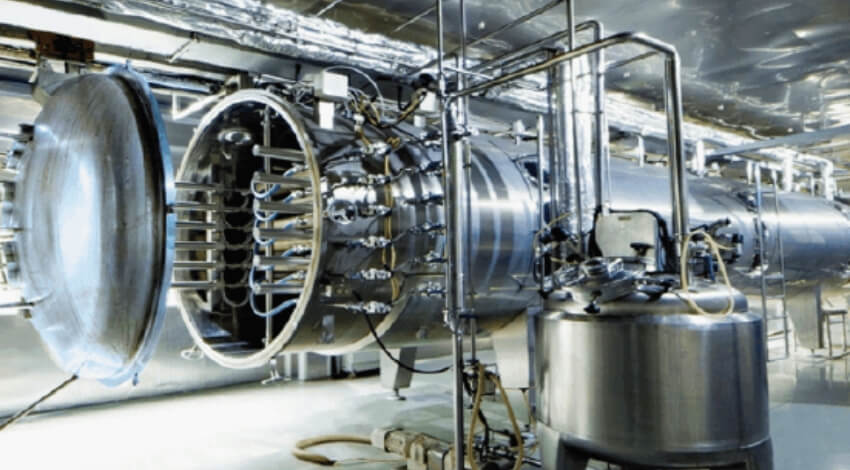

Vacuum Low Temperature Liquid Continuous Drying Equipment

Quality Control

Our skilled team and advanced systems ensure that only top-quality products reach our customers.

Quality Checks